Cultured meat—produced by growing animal cells in vitro—is poised to transform the protein supply chain. It offers a way to reduce reliance on land and water, lower greenhouse gas emissions from traditional livestock farming, and deliver a more sustainable food source. With advancing technology, supportive policies, and growing consumer acceptance, the global cultured meat industry is now moving from experimental development toward commercial expansion.

In recent years, countries like Singapore, the U.S., and Israel have approved cultured meat products from 10 companies, with six new products cleared in 2025 alone—highlighting progress in both regulation and market demand. The need for scalable, cost-effective cultured meat solutions is growing more urgent.

Cultured Meat Production Process

1.Harvest “seed cells,” such as muscle stem cells, from animals in a safe and non-harmful way, then establish stable, proliferating cell lines through cell banking.

2.Grow cells in large-scale bioreactors using multi-stage amplification to achieve exponential growth. Common bioreactors include stirred-tank, wave-mixed, and airlift systems.

3.Adjust culture conditions to guide cells into mature types, like muscle fibers and fat. Use tissue engineering methods—such as edible scaffolds and 3D bioprinting—to assemble cells into three-dimensional muscle tissue structures.

4.Finally, harvest, wash, season, color, and shape the tissue into a product that matches traditional meat in texture, flavor, and nutritional profile.

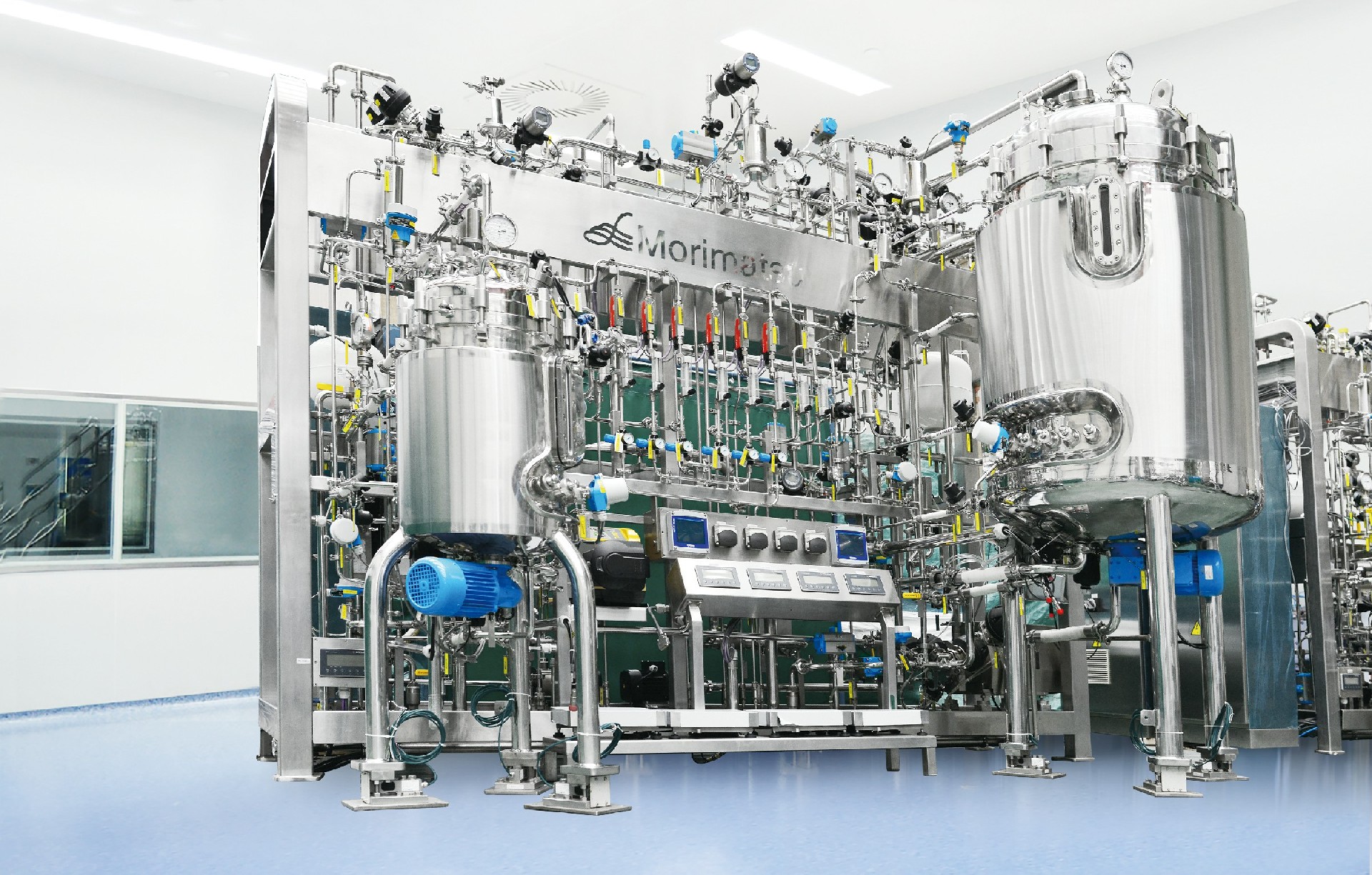

Morimatsu Cell-Based Meat Solutions

In cell-based meat production, bioreactors and their supporting systems are the “heart” of the process, directly impacting efficiency, product quality, and cost. Advances in reactor technology and engineering are key to scaling cell-based meat from the lab to commercial production.

Morimatsu brings deep expertise to this field, with proven success using 10,000-liter reactors deployed internationally. Leveraging its advanced reactor design and manufacturing capabilities, Morimatsu delivers customized solutions that support the full production process for cell-based meat companies.

1. 500L Stainless Steel Bioreactor

· Designed for high-density suspension culture of avian and mammalian cells.

· The 500L pilot-scale bioreactor allows validation of critical process parameters, providing reliable data for scaling up to 2,000L or even 10,000L production lines.

2. 500L Media Preparation System + 1,000L Feeding System· Enables precise nutrient feeding and optimized media circulation.

· Continuous improvements have driven a roughly 70% reduction in core material costs—such as serum-free media—over the past three years, with equipment upgrades playing a key role in this cost efficiency.

3. Integrated CIP (Clean-in-Place) System

Automated cleaning and sterilization eliminate cross-contamination, ensure compliance with global food safety standards, and provide a robust quality control barrier.

4. Full-Process Automated Control and Data Traceability

Enables digital, automated management across the entire production process, supporting full traceability and reliable quality assurance.

5. Modular Design and Flexible Production

Easily adaptable to different cell types—such as chicken, pork, and salmon—this modular system supports customized production needs and provides flexibility for diversified industrial applications.

This solution meets both GMP and food safety standards while boosting production scalability and operational efficiency through modular design and process optimization. It lays the engineering groundwork for future 10,000-ton commercial production lines and serves as a key driver for cost reduction and efficiency gains in the cell-based meat industry.

Morimatsu continually drives technological innovation to meet industry needs, staying aligned with global trends in cell-based meat. By advancing reactor scale, precision, and intelligence, we help clients seize opportunities in the evolving global protein market. As the industry moves into commercialization, the performance of core bioreactors will directly influence development speed and product quality. Morimatsu remains committed to innovation, solution optimization, and industry collaboration—turning cell-based meat from a pioneering concept into a mainstream food option while supporting sustainable development and the advancement of global food technology.

About Morimatsu LifeSciences

Morimatsu LifeSciences is a key business segment of Morimatsu International Holdings Limited (Stock Code: 2155.HK). It comprises Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., Ltd., Morimatsu (Suzhou) LifeSciences Co., Ltd., Shanghai Morimatsu Biotechnology Co., Ltd., Shanghai Mori-Biounion Technology Co., Ltd., Shanghai Morisora Technology Co., Ltd., Bioengineering AG, Pharmadule Morimatsu AB, and its affiliated companies.

Morimatsu LifeSciences is dedicated in providing core equipment, process systems, and smart modular facility solutions, and services for the pharmaceutical, biopharmaceutical, medical aesthetics, and fast-moving consumer goods (FMCG) sectors including (cosmetics, food, and health supplements), as well as data centers.

Our team comprises highly experienced professionals with deep expertise in process R&D, engineering design, advanced manufacturing, compliance and validation consulting, production execution, and intelligent operations. With broad experience across diverse industries, we fully understand the unique characteristics and process requirements of various products. This enables us to deliver tailored, end-to-end process solutions from the conceptual design stage, precisely aligned with client’s specific needs.

Morimatsu LifeSciences has established a strong global presence, supported by advanced R&D centers, design hubs, and state-of-the-art manufacturing facilities worldwide. Our well-established service network spans Europe,USA,Asia-Pacific, and emerging markets. We have successfully delivered outstanding, customized solutions to clients in over 40 countries and regions, gaining extensive experience in international project execution.

As a multinational enterprise with core strengths in process technology, modular facility construction, and intelligent manufacturing, Morimatsu LifeSciences is dedicated to meeting the evolving equipment and system needs of our key industries. Through continuous innovation and technological advancement, we are steadily expanding our global footprint, driving our international strategy forward, and delivering Morimatsu’s expertise, reliability, and innovation to the global life sciences and related sectors.