Search

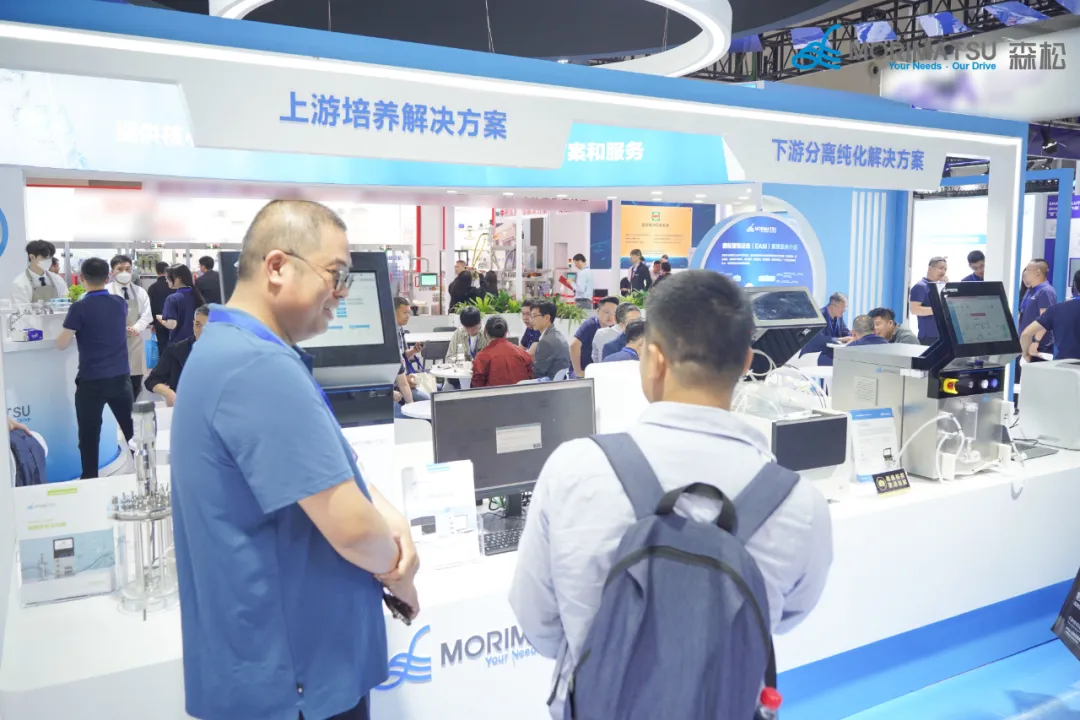

On April 23, the 66th National Pharmaceutical Machinery Exposition opened grandly at the Chongqing International Expo Center. Pharmaceutical equipment and service companies from around the world, along with tens of thousands of professional visitors, gathered in the vibrant mountain city for this premier international event, which seamlessly integrates trade cooperation, technical exchange, and industrial innovation.

With deep industry insight and forward-looking vision, Morimatsu continues to accurately anticipate the direction of industrial upgrading. We remain committed to a dual-drive strategy of technological innovation and product research and development. Through a core technology layout that closely aligns with market dynamics and customer needs, the innovative solutions and intelligent operation and maintenance systems we showcased at this year’s event garnered significant attention, earning widespread recognition and high praise from industry peers and customers alike.

01 Total Laboratory Solution

Our offerings encompass upstream cultivation solutions and downstream separation and purification solutions, designed with robust, reliable, streamlined, and highly efficient workflows to significantly enhance customers' R&D efficiency.

Morimatsu’s 2D Wave Bioreactor features a unique two-dimensional motion mode that creates a low-shear environment while delivering exceptional oxygen transfer performance. Available in a range of specifications with a disposable closed system design, it significantly reduces the risk of contamination.

Our flexible Glass Bioreactor is ideal for both cell and microbial cultures. Offering a variety of volume options and highly customizable single, dual, or multi-reactor configurations, it can be tailored precisely to meet specific research and production needs.

Designed to support IC/ID/LS processes, our Single-Use Online Liquid Preparation/Cracking System accommodates a wide range of production scales. With a modular, integrated design, the system ensures high deployment Accuracy.

Our Intelligent Microfluidic Synthesizer serves the R&D of nano drug delivery system. Featured intelligent operation and smooth chip simulation support, it can help customers efficiently screen and optimize formulations, reduce test costs and accelerate optimization progress.

02 Single-Use Solution

Morimatsu’s Single-Use Systems are available in various specifications to fit multiple brands of equipment, with stable product processes, safe and reliable quality, and comprehensive validation document support.

Morimatsu’s Single-Use Bioreactor offers comprehensive solutions for full process scale-up. Featuring advanced automation and modular system design, they support a variety of installation schemes and multi-strain co-culture applications. With flexible configuration options and tailored customization services, they provide versatile support for diverse bioprocessing needs.

03 Solid Preparation and API Process Solutions

The Multi-functional Fluidized Bed is equipped with easily interchangeable product pot modules, enabling multifunctional granulation, drying, and coating operations on a single machine. This ensures flexibility for product development and process improvement.

The Wet Granulator with smooth speed control provides precise parameters for operation; the switchable product pot module may meet your needs for different throughputs in experiments.

The WD Multifunctional Filtration and Washing Dryer combines filtering, washing, and drying operations in a single unit. With simplified process flow and full-automatic control, it boosts production efficiency and minimizes pollution.

Designed specifically for laboratory-scale spray drying research and development, our Spray Dryer ensures seamless process transfer from experimental trials to batch production by maintaining consistent process parameters, facilitating smooth and efficient scale-up.

04 On-line Liquid Dispensing System

The overall modular wrapped design reduces users' labor cost and saves clearing time. Applying online analysis technology, the system can run the free-built formulas fully automatically to serve meet multi-scenario applications.

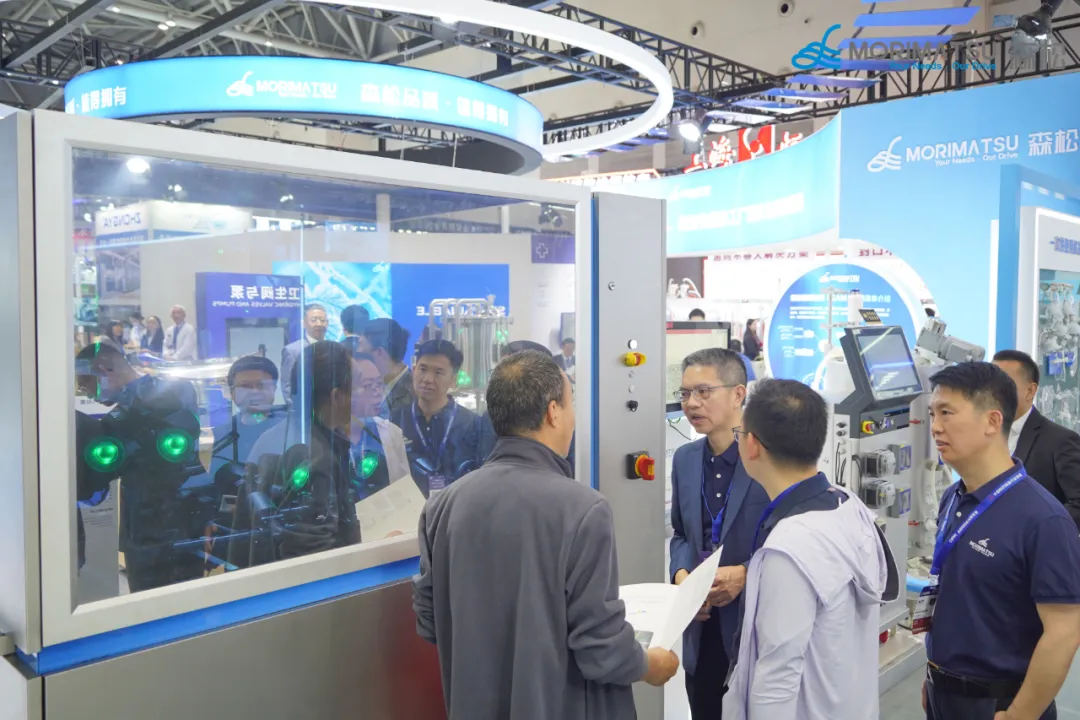

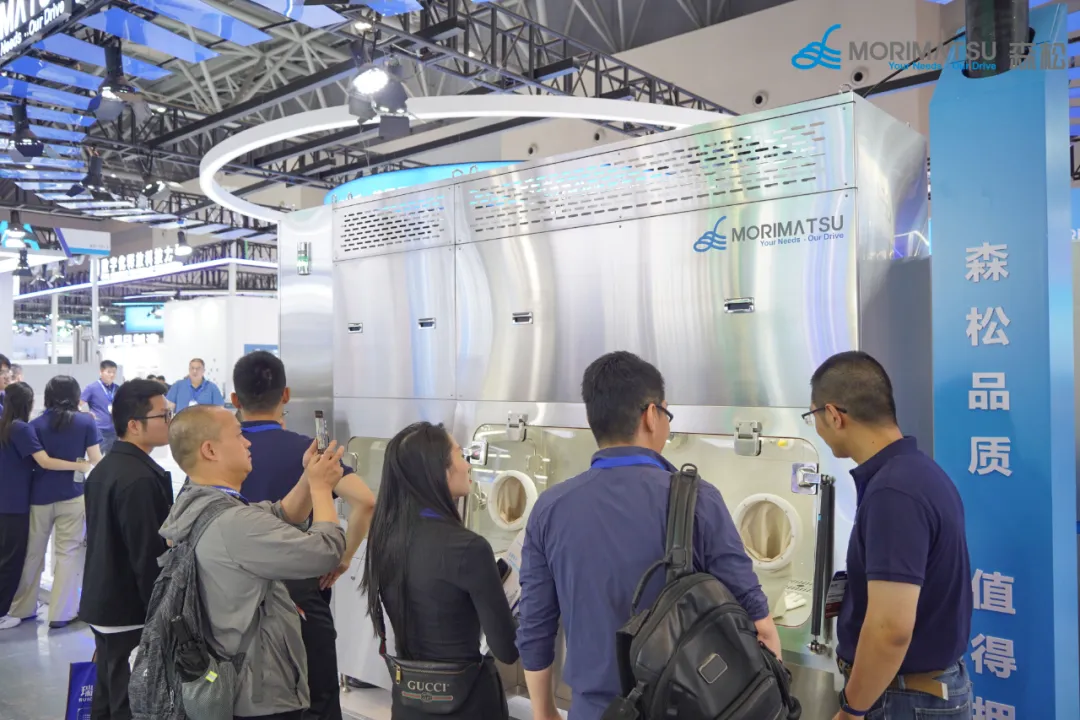

05 Isolator Solution

Morimatsu’s isolators integrate advanced technologies, featuring automated control, real-time monitoring, and deviation alarms. They deliver robust protection for products while ensuring the safety of operators.

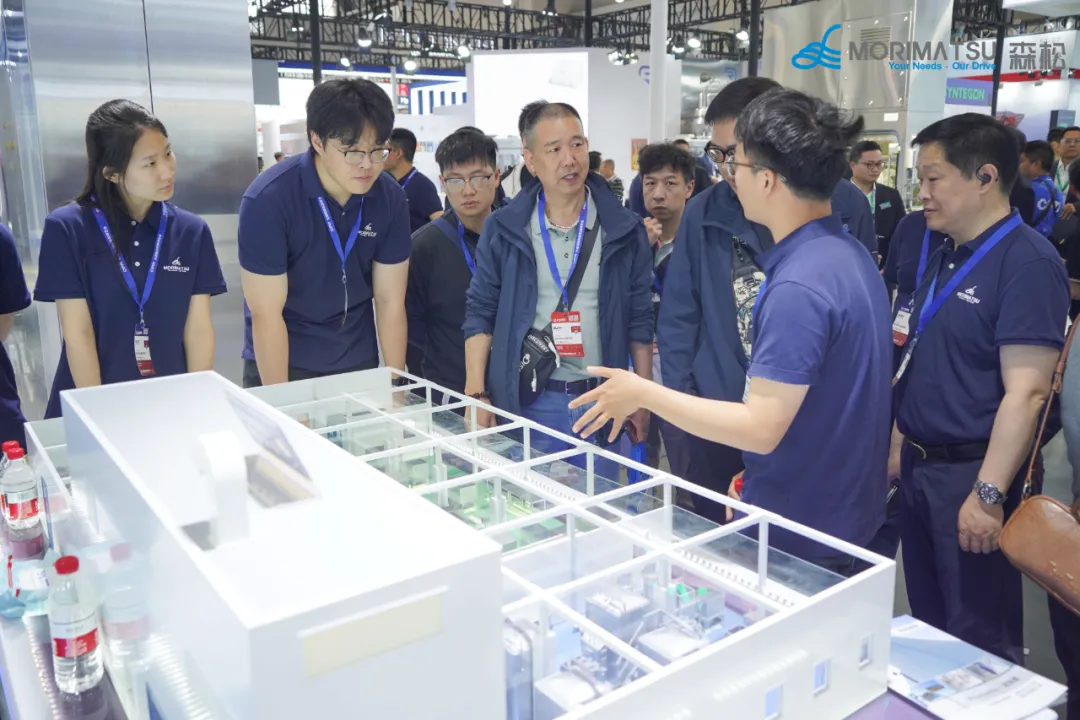

06 Total Plant Solution

Morimatsu's modular plant offers a turnkey total solution from design to validation, saving time in constructing new plant buildings and significantly reducing on-site construction. This enables overall off-site relocation of the building, meeting pharmaceutical companies' needs for rapid product launches and flexible production expansion.

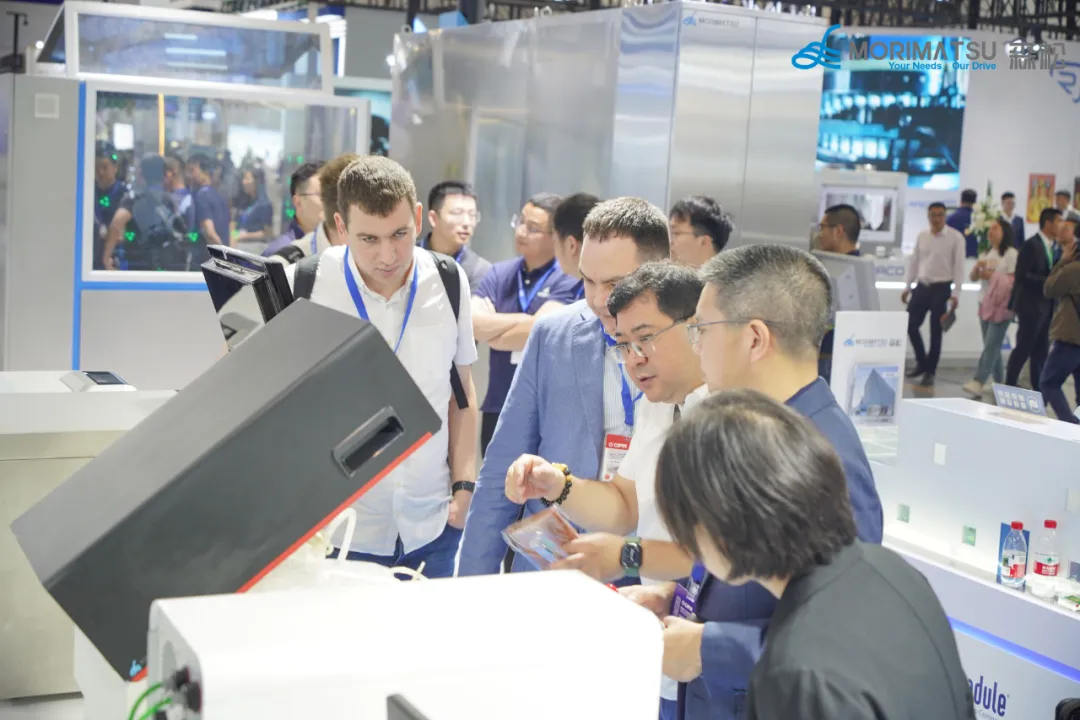

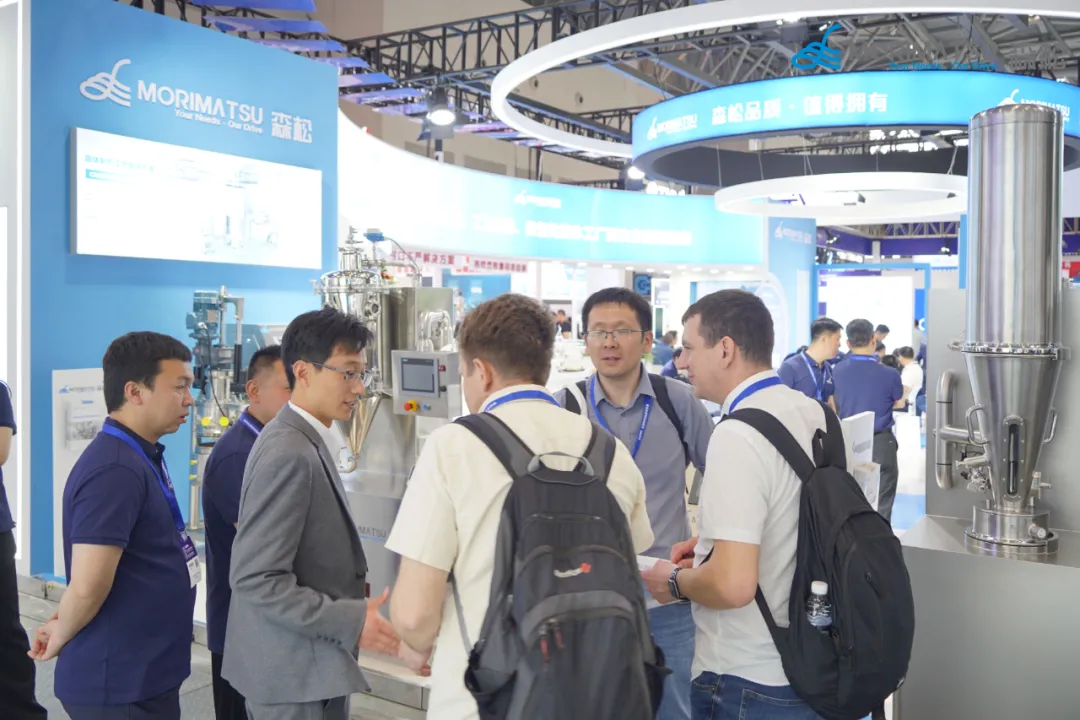

During the event, Morimatsu actively engaged in industry exchanges and conducted in-depth trade negotiations with partners across the sector. In addition to sharing the latest breakthroughs and practical application experiences in scientific research, Morimatsu held comprehensive discussions on core technical challenges, emerging industry trends, and new areas for innovative growth — jointly exploring fresh momentum and potential opportunities within the field. Morimatsu also conducted extensive market research to gather valuable customer feedback, using these insights to strengthen project collaborations both domestically and internationally, expand its business footprint, and identify shared growth opportunities.

Amid the rapid advancement of the global biopharmaceutical industry, Morimatsu remains anchored in technological innovation. Leveraging its deep technical expertise and scenario-driven insights, we deliver full life cycle solutions that address critical customer pain points, accelerate research and development timelines, and open new frontiers in biopharmaceuticals — contributing Morimatsu’s strength to the advancement of human health worldwide.

About Morimatsu LifeSciences

Morimatsu LifeSciences, one of the key business segments of Morimatsu International Holding Co., Ltd. (Morimatsu International, stock code: 2155.HK), mainly consists of Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., Ltd., Morimatsu (Suzhou) Life Technology Co., Ltd., Shanghai Morimatsu Biotechnology Co., Ltd., Pharmadule Morimatsu AB (Sweden) and its subsidiaries, which serves the pharmaceuticals, bio-pharmaceutical, cosmetic medicine, FMCG (cosmetics, baby, women & home Care, health care, fabric & home care, food, beverage, nutraceuticals) and other industries, providing customers with "core equipment+value-added services+digital intelligent overall factory solutions and services" ("MVP Solutions&Services"), focusing on core equipment, stainless steel process systems, disposable process systems, consumables, laboratory solutions, digital and modular factory solutions and services.

As a diversified multinational company, Morimatsu has opened subsidiaries or advanced manufacture plants in China, Japan, Sweden, United States, India, Italy, Singapore, and has delivered different forms of products and services to more than 40 countries and regions so far, by its global footprint of an efficient and professional team.

Forward-Looking Statements

The information in this press release may include some forward-looking statements. Such statements are essentially susceptible to considerable risks and uncertainties. The use of "predicted", "believed", "forecast", "planned" and/or other similar words/phrases in all statements related to our company is to indicate that the statements are forward-looking ones. Our Company undertakes no obligation to constantly revise such predicted statements.

Forward-looking statements are based on our Company management's current perspectives, assumptions, expectations, estimations, predictions and understanding of future affairs at the time of the making of such statements. Such statements are not guarantees of future development and are susceptible to the impact of risks, uncertainties and other factors; some are beyond the control of our Company and unpredictable. Subject to the influence of future changes and development in our business, competition environment, political, economic, legal and social conditions, the actual outcomes may differ significantly from the information contained in the forward-looking statements.