Search

Proper equipment maintenance is essential to prevent contamination risks, probe damage, or system malfunctions. Let’s begin with the correct storage practices for fermenters.

1.Fermenter Maintenance

01 Cleaning and Sterilization

Thoroughly clean all material-contact surfaces of the fermenter, including the vessel, pipelines, agitators, instrument probes, and related components.

Performing CIP and SIP on all process-contact areas is recommended to minimize residual bioburden and ensure system integrity.

02 Dry Storage

Dry storage is recommended: ensure that all equipment and pipelines are completely drained of moisture, and purge with dry heated air if necessary.

If the downtime is relatively short and conditions allow, the material-contact areas of the system may be filled with clean compressed air to maintain a slight positive pressure.

03 Electrode Storage

pH and dissolved oxygen electrodes should be removed and stored separately.

pH electrodes should be stored in dedicated electrode storage solution or in 3M KCl solution.

Optical dissolved oxygen electrodes should be kept clean, with the membrane dry during storage.

04 External Maintenance

Inspect seals, valves, and agitator bearings for any residual liquid or deposits to prevent corrosion. Ensure the tank exterior and all connections remain clean and dry.

05 Before Reuse

Before placing equipment back into service, assess whether an additional CIP and SIP cycle is required, based on the validated preservation period and cleaning verification results.

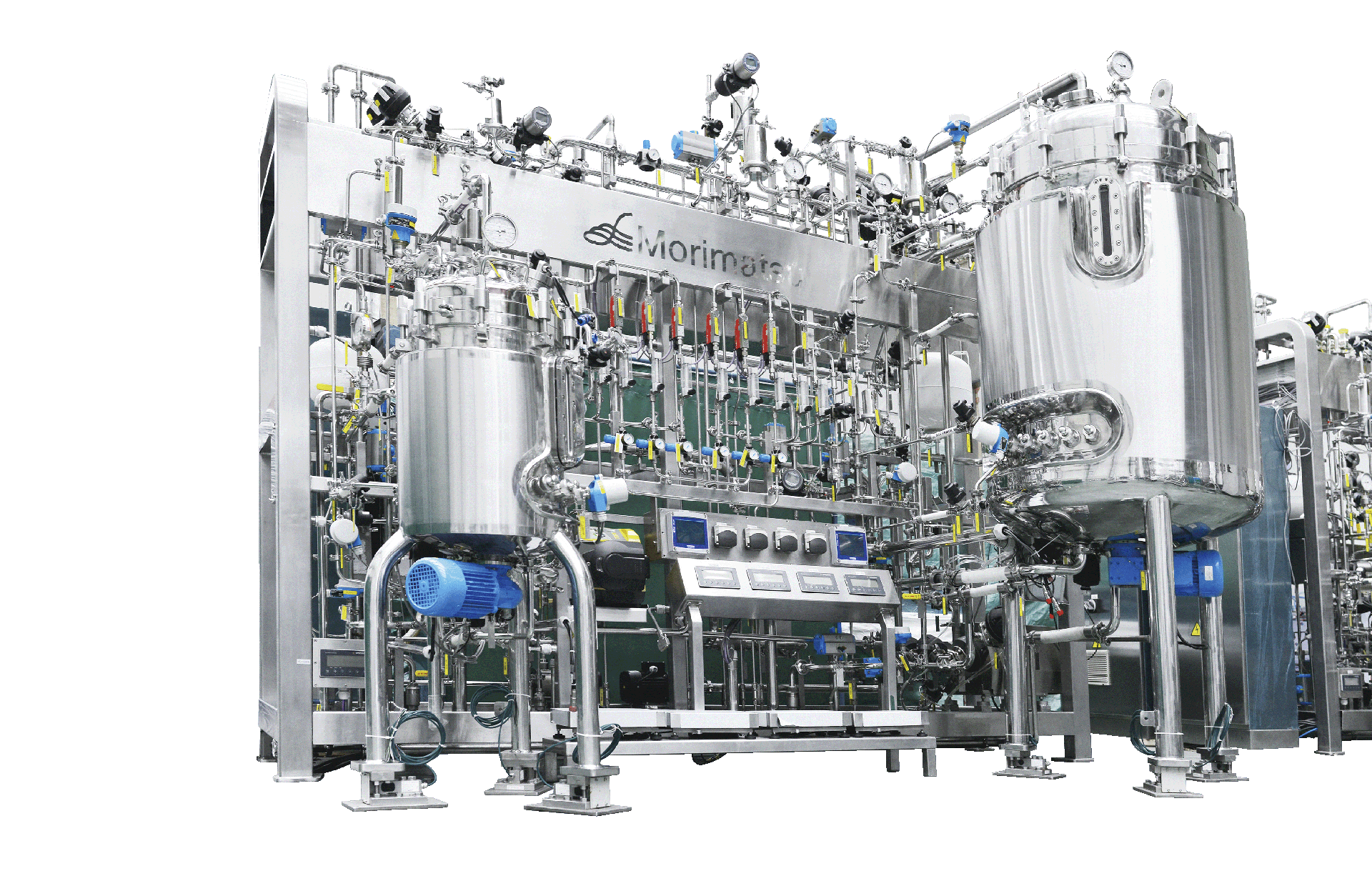

Morimatsu Bioreactor and Fermentation Tank Systems

For fermentation tanks, dry preservation is recommended. For laboratory chromatography systems, wet preservation is preferred, as their storage requirements prioritize bubble prevention and microbial growth control.

2.Chromatograph Maintenance

01 Chromatography Column

Preservation with a 20% ethanol solution is generally sufficient to prevent microbial growth.

Seal all inlets and outlets with dedicated column end caps to minimize ethanol evaporation and to prevent column bed drying or cracking.

02 System Tubing

Flush the system thoroughly with ultrapure water or WFI to remove saline residues, ensuring no salt remains in pump heads or valves that could cause crystallization and blockage.

Fill the tubing with 20% ethanol or a dilute alkaline solution to maintain sterility and prevent salt crystallization. Seal the tubing ends to minimize liquid evaporation and to avoid microbubble formation in narrow channels.

03 Electrode Storage

pH electrodes should be stored in dedicated electrode storage solution or in 3M KCl solution.

After cleaning, store conductivity meters dry in dedicated professional storage cases.

04 External Maintenance

Keep the system clean, free of dust, and dry.

Check all tubing connections for leaks to prevent loss of the storage solution.

05 Before Reuse

Rinse the system thoroughly with water to completely remove the storage solution and prevent any residue from affecting test results. After rinsing, equilibrate the system with the appropriate buffer.

Morimatsu Benchtop Chromatography System

Proper cleaning and storage protect the precision components of the chromatography system, prevent air ingress and contamination, and ensure rapid resumption of experiments after holidays.

Standardized maintenance procedures reduce the likelihood of equipment failure, keeping systems.

About Morimatsu LifeSciences

Morimatsu LifeSciences is a key business segment of Morimatsu International Holdings Limited (Stock Code: 2155.HK). It comprises Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., Ltd., Morimatsu (Suzhou) LifeSciences Co., Ltd., Shanghai Morimatsu Biotechnology Co., Ltd., Shanghai Mori-Biounion Technology Co., Ltd., Shanghai Morisora Technology Co., Ltd., Bioengineering AG, Pharmadule Morimatsu AB, and its affiliated companies.

Morimatsu LifeSciences is dedicated in providing core equipment, process systems, and smart modular facility solutions, and services for the pharmaceutical, biopharmaceutical, medical aesthetics, and fast-moving consumer goods (FMCG) sectors including (cosmetics, food, and health supplements), as well as data centers.

Our team comprises highly experienced professionals with deep expertise in process R&D, engineering design, advanced manufacturing, compliance and validation consulting, production execution, and intelligent operations. With broad experience across diverse industries, we fully understand the unique characteristics and process requirements of various products. This enables us to deliver tailored, end-to-end process solutions from the conceptual design stage, precisely aligned with client’s specific needs.

Morimatsu LifeSciences has established a strong global presence, supported by advanced R&D centers, design hubs, and state-of-the-art manufacturing facilities worldwide. Our well-established service network spans Europe,USA,Asia-Pacific, and emerging markets. We have successfully delivered outstanding, customized solutions to clients in over 40 countries and regions, gaining extensive experience in international project execution.

As a multinational enterprise with core strengths in process technology, modular facility construction, and intelligent manufacturing, Morimatsu LifeSciences is dedicated to meeting the evolving equipment and system needs of our key industries. Through continuous innovation and technological advancement, we are steadily expanding our global footprint, driving our international strategy forward, and delivering Morimatsu’s expertise, reliability, and innovation to the global life sciences and related sectors.